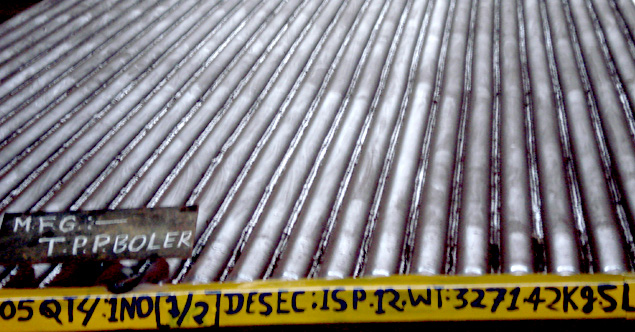

Water wall panels are used in modern day boilers in place of steam generating tubes to reduce heat loss due to their gas tight nature and reduce insulation costs.

Water wall panel welding machine.

Published on mar 7 2019.

All panels normally produced have side fins without extra work.

Rear water wall panel nose panel.

Find the welding water cooler and water coolant system that can fit your welding applications at grainger.

Membrane wall panel welding machine boiler membrane wall panel welding machine membrane panel welding machine saw tube diameter ø 22 76mm tube wall thickness 3 10mm width of fin bar 8 120mm.

Membrane water cooled wall tube panel welding line is used for the fabrication of all specifications of tube panel products which is mainly composed of flat steel finishing and cutting machine.

The system increases safety of workers and works with high productivity.

It is possible to manufacture wide range of panel widths flexibly.

Skip trial1 month free.

Understanding the needs of our customer reliable equipment modern processes and the constant development of our products is key when it comes to securing business.

Pema flexible panel production makes it possible to have first step investment extended to meet various production expansion needs.

With pema welding equipment for membrane wall panels tube welding and cutting tube prefabrication etc.

This feature is not available right now.

Boiler header small hole auto welding machine duration.

We fabricate water wall panels using automatic fin to tubes welding machines and large tube panel benders to achieve desired shape of panels which can have swaged ends stub welded to headers.

Please try again later.

Find compact powerful welding water coolers from grainger to help keep your valuable welding machines from becoming dangerously overheated.

Rating is available when the video has been rented.

Shop online for easy ordering.

Sun way 346.

Custom made design enables enlargement of equipment from service station to mass production.

The number of welding heads can be increased for more capacity.

Short adjustment time between product changes.

It is possible to weld panels with pri bent openings.

You get the most of your production.

To avoid any heat affected zone haz on the boiler tubes of the water wall panels the sawing of the defective panel wall tubes should be done not by flame cutting but instead with the bwc cutting system that uses abrasive saws.